About Tronox

Tronox is a global leader in the mining, production, and marketing of inorganic minerals and chemicals and operates two vertically integrated divisions.

Tronox is a global leader in the mining, production, and marketing of inorganic minerals and chemicals and operates two vertically integrated divisions.

The TiO2 division mines and processes titanium ore, zircon, and other minerals, and manufactures TiO2 pigments. They are the third-largest titanium feedstock producer with approximately 10% of global titanium ore production, and the second-largest producer of zircon, with approximately 20% of global production. The division operates mines and mineral processing plants in South Africa and Australia, and pigment manufacturing plants in the United States, the Netherlands, and Australia.

The Challenge

Tronox’s project management office (PMO) team encountered difficulty managing projects and building an effective plan for projects in the active pipeline. Planning and tracking of project work was being done manually, with information coming from multiple systems and spreadsheets. This method led to difficulty in daily updates and progress measurement, increased errors, and a lengthy approvals process. Schedule progress with cost information was also analyzed manually using spreadsheets. Budget and contract management in Tronox’s existing ERP system lacked the depth required to address the PMO team objectives.

Tronox wanted to implement a system to manage the entire portfolio of capital projects for Tronox Mineral Sands (TMS). They also wanted to manage the performance of their project portfolio using tools like earned value management

(EVM), cash flow dashboards, and commitments by fund sources.

The Solution

Gaea fully automated Tronox’s formerly-manual processes by implementing Primavera Unifier and P6 EPPM, and integrating both with SAP. Gaea’s team designed, configured, enhanced, and deployed nearly 60 complex and unique business processes. They set up a facility breakdown of Tronox assets in order to manage medium, large, and mega projects that were distributed across various portfolios. In addition, a facility breakdown structure was also created for effective management of assets under construction.

Reports and dashboards for key performance indicators (KPIs) were developed using Oracle BI Publisher, and a system was designed to generate project cash flows and earned value curves in Unifier.

Reports and dashboards for key performance indicators (KPIs) were developed using Oracle BI Publisher, and a system was designed to generate project cash flows and earned value curves in Unifier.

Return On Investment

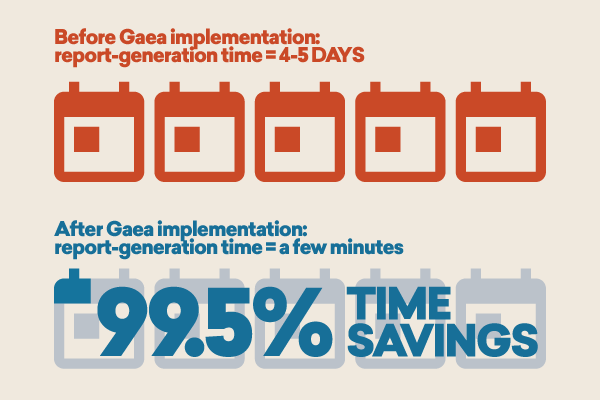

After implementation, the time required to generate reports was reduced by 99.5%, from 4-5 days to a few minutes. Gaea’s development of effective cost-control and value-engineering processes reduced Tronox overhead by 25%. Management of contingency budgets was greatly improved, and the variance in contract cost by vendor type was reduced.